Polytetrafluoroethylene – sounds strange, can do a lot and we are the experts for it.

From manufacturer to full-service PTFE expert.

Shortly after the foundation, we accompanied the product development of our clients and customers with our constantly growing PTFE know-how. Today we are recognized as a PTFE product developer as well as a PTFE manufacturer. Innovative PTFE plastic solutions that bear our technical signature are in use all over the world.

Our supportive construction convinces with tailor-made and application-related developments for customer-specific products in various industries. Our pioneering equipment enables us to implement technically sophisticated finished parts, based on drawings or samples, in prototypes, that can be produced in small and large series.

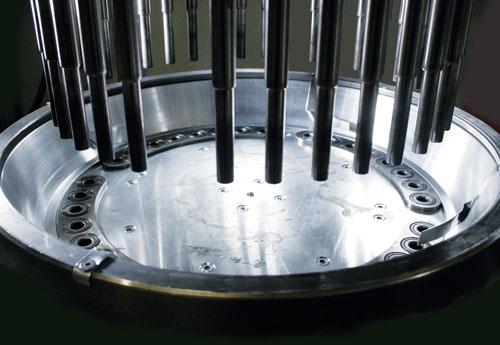

And with our modern, powerful machinery in the manufacturing center, we create the basis for the manufacture of extremely high quality products and their individual post-processing.

Beichler & Grünenwald relies on different manufacturing processes.

Product diversity requires to have the right manufacturing processes at one’s disposal. We can use practically every PTFE manufacturing process in-house, from RAM extrusion to hydraulic and isostatic pressing processes to CNC-controlled turning and milling as well as automatic turning. Depending on the requirement profile, products are coated or powder-coated; Parts and materials are lined or coated with PTFE. In addition to the production and manufacture of extrudates, semi-finished products and coatings, Beichler & Grünenwald itself supplies complex assemblies from a single source. Beyond assembly, additional processing such as thermal forming, welded connections, laser marking or ultrasonic cleaning is usually done.

Polytetrafluoroethylene can be combined excellently with other materials to reinforce the desired properties. For many companies, Beichler & Grünenwald is the first point of contact when it comes to producing and processing compounds with mineral or organic fillers for customer-specific requirements.

We have been certified according to DIN EN 9001 since 1996

Competence for polytetrafluoroethylene through in-depth knowledge.

Creative, powerful and very innovative – we really act on conviction concerning plastic solutions with the unique material PTFE.

Across industries, we stand for sophisticated solutions in the fields of extrusion, welding, pressing and sintering of PTFE. Our grown know-how and a team of recognized PTFE experts enable innovations far beyond known applications and give customers a sustainable competitive advantage in terms of production safety and environmental compatibility.

For our customers, we develop functionally and cost-optimized solutions made of the high-performance plastic PTFE that convince even under the toughest conditions and under the greatest loads: thanks to the outstanding material properties of polytetrafluoroethylene.

“At the end of the day, we want to make the world a bit better together with our products and our actions,” is the vision of the company's management.

Sustainable, visionary, responsible - WE wins.

Sustainable, resource-saving and environmentally friendly business practices and responsible cooperation characterize our thinking and acting. Curiosity, openness, fairness and personal responsibility are motivation, but also a benchmark for the performance of our company. However, our self-image also includes our enormous quality standards relating to products and development potential – we don’t stop there, but look ahead. The statement “the next step” shapes us in every respect.

We combine energy with visions and continue our success story.

The material PTFE with its unmatched properties as well as special PTFE mixtures with various fillers and other high-performance plastics are the base material, which is processed on the basis of innovative concepts and processes to extrudates, semi-finished products, coatings and construction parts, which are considered as the best.